|

|

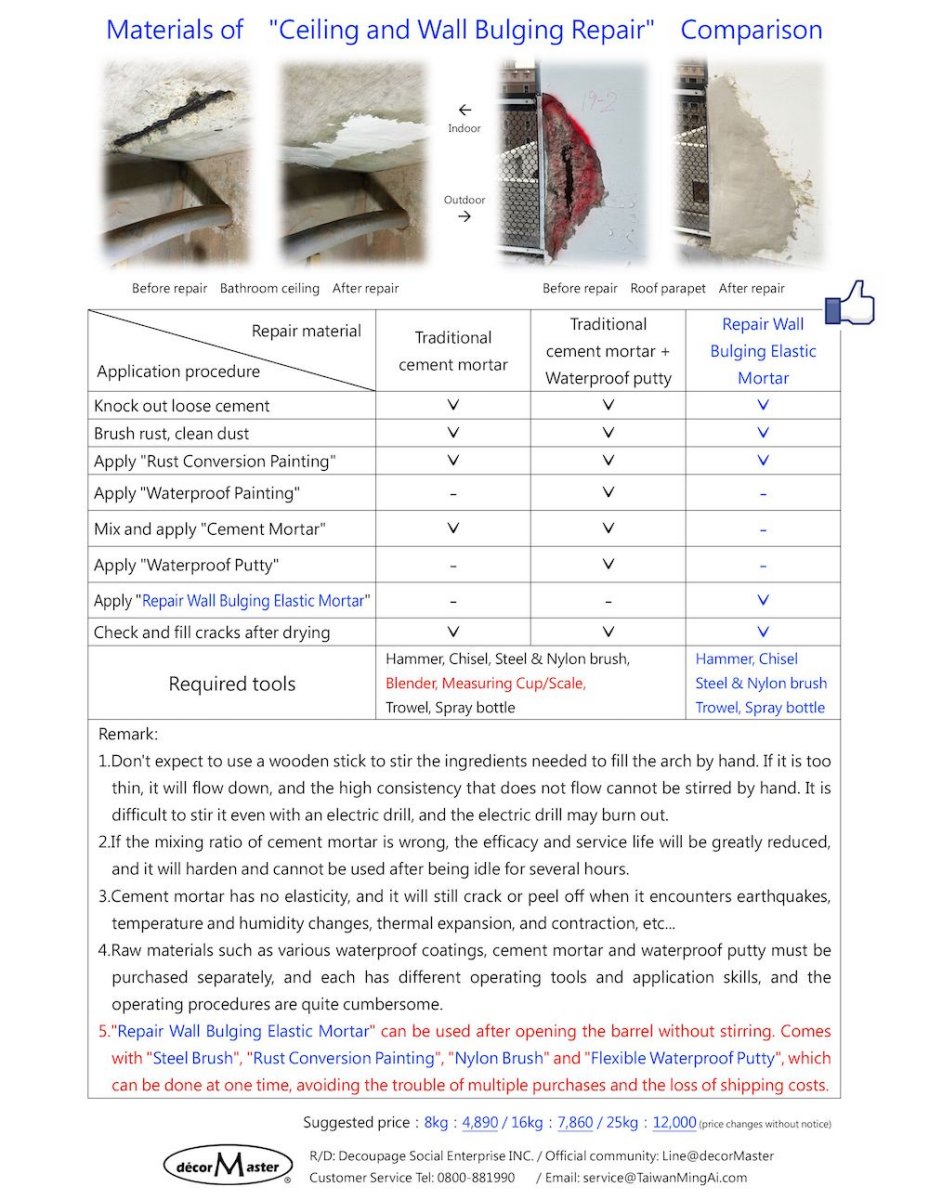

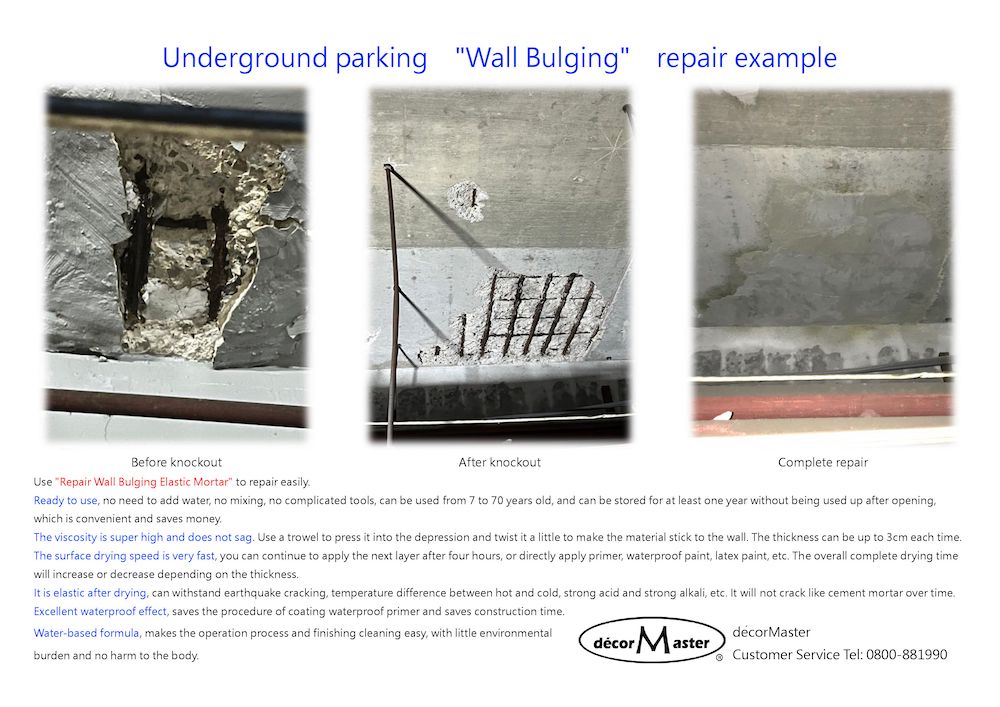

[ Repair Wall Bulging Elastic Mortar ] Apart from cement mortar, there is currently a lack of readily available materials on the market that can effectively and simply repair "Ceiling and wall bulges (Cracks and Swelling)". Even when hiring professional plastering teams, they still use cement mortar for repairs. Not only is this costly and has a limited warranty period, but finding skilled and conscientious craftsmen is becoming increasingly difficult. For those without home repair experience, attempting DIY repairs is even more challenging. This product has been specifically developed to address the issue of self-repairing wall bulges. Unlike traditional cement mortar, it offers non-drip properties, earthquake-resistant elasticity, exceptional waterproofing, strong adhesion to smooth surfaces, rapid drying, and resistance to high concentrations of acidic and alkaline solvents. Currently, there are no similar materials available on the market.   |

|

[ Feature ] 1. Water-based formula, odorless, easy to apply and finish, devoid of lime content, gentle on hands. 2. Ready for use upon opening, no need for self-mixing, blending, or preparation. Unused material can be stored for up to a year. 3. Extremely high adhesive strength, inherent superior waterproofing capability, and resistance to strong acids and alkalis. 4. Retains flexibility after drying, able to withstand drastic temperature changes, UV exposure, and seismic forces. 5. Simple and easily obtainable tools for operation, suitable for ages 7 to 70.   |

|

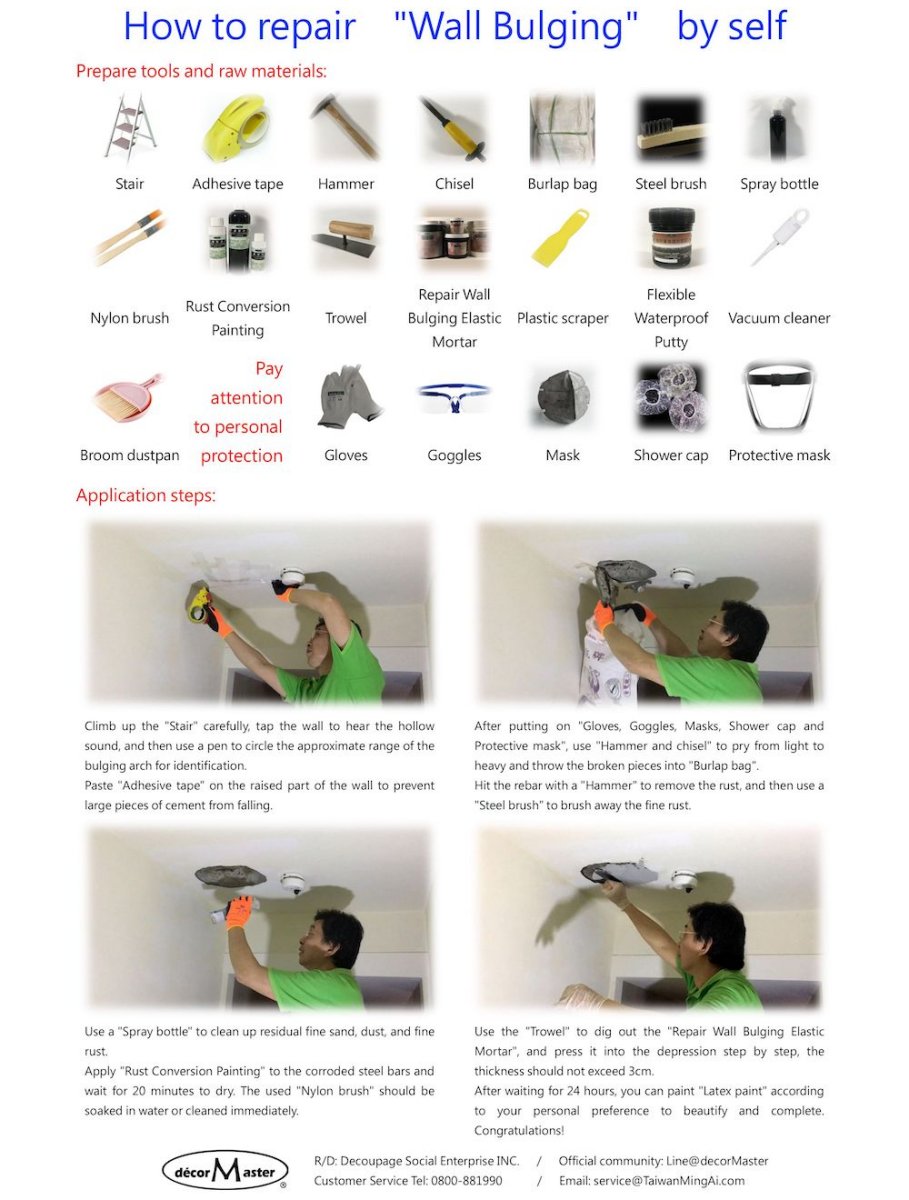

[ Instructions ] Ensure that the wall surface you intend to treat is clean. Remove any loose cement chunks and wipe away dust with a damp cloth. Especially focus on thorough cleaning for dirt, dust, sand, oil stains, or mold. Next, take this product and apply it directly to the recessed area, then smooth it out. |

|

[ Demo Video ] |

|

[ Precautions ] 1. Try to knock out loose cement blocks, please pay attention to the safety protection of yourself, others and furniture during the process. 2. Use a brush, air spray gun, etc. to clean up the dust after knocking out the cement blocks. 3. Use a trowel or a scraper to dig out the raw materials, spray some water on the wall, and press the raw materials up hard to increase the adhesion. 4. After pressing it up, turn the trowel or scraper lightly a few times and pull it sideways to prevent the raw material from falling off. 5. Increase the coating range step by step, and each time you need to cover more than 1/4~1/3 of the original coating range. 6. Then you can apply it multiple times to increase the thickness, in the same way as the aforementioned points 3 to 5. 7. The maximum thickness should not exceed 3cm, and holes that are too deep need to be filled many times to avoid the whole piece falling off and working for nothing. 8. For corners and pits that are difficult to operate, you can dig out the raw materials with your fingers, and then insert them slowly and forcefully. 9. The complete drying time is related to the coating thickness and ambient temperature and humidity. 10. For potholes with a depth of less than 3cm, you can continue to the next step after 6 hours. 11. There may be a little cracks on the surface after it is completely dry if it is not pressed hard or the raw material is not applied enough, just use "Flexible Waterproof Putty" to fill it up. 12. Do not discard the raw materials that fall during the operation, they can be collected back into the container and stirred for further use. 13. During the filling process, the edge of the pothole may be uneven with the original wall surface, which can be smoothed with a wet rag. 14. If you still feel a little uneven after the completion, you can use "Ultra Anti cracking Waterproof malleability Putty" to smooth it. 15. The texture of this product is soft, elastic and anti-earthquake. It should not be regarded as a raw material that can replace cement mortar. [ Main ingredients ] Ion water, water-based resin, stone powder, special additives, free of harmful ingredients such as heavy metals, formaldehyde, and benzene-based volatiles. [ Precautions ] After opening, please use up as soon as possible. If not used up, please seal the outer package tightly and put it in a cool and dry place to prevent it from drying up. Do not let children eat it by mistake. In case of emergency, please rinse with plenty of water. |

|

[ Note ] If it is not used up after use, keep it for the next use. Please be sure to seal the plastic bag tightly before storage to prevent blockage. If you have any questions about operation, please call us at 0809-000881. |

|

[ Rust Conversion Painting ] Suitable for indoor and outdoor anti-rust needs, if there is already slight rusting, applying this product directly can generate anti-rust effects.  |

|

[ Feature ] 1. Requires only rust removal with an iron brush before application, saving a significant amount of manpower and time. 2. Water-soluble formula allows for easy application and can be used on any iron-made product. 3. With a soft texture, it can endure extreme bending or stretching without surface cracking. 4. Transforms iron rust into stable purplish-black passivation, preventing further rusting. If there is no color change after application, the material may not be iron-based. |

|

[ Instructions ] 1. The product may settle over time, so please shake well before use, and do not dilute with water. 2. Begin by removing grease, dirt, salt deposits, and loose rust particles from the corroded surface. 3. It is recommended to apply using a nylon brush or a roller brush. Surface drying time is approximately 15-20 minutes. For reapplication, wait for at least 4 hours, and do not exceed 7 days. 4. For certain metals with unique surface compositions, the applied coating might not turn purplish-black. However, even if the surface does not change color due to an existing layer of paint, the anti-rust functionality will still be effective. |

|

[ Precautions ] 1. Before applying, pour the product into another container and then use a brush for application. Do not pour any unused product back into the original bottle. 2. During usage, prevent iron rust from falling into the product bottle to avoid contamination that might affect the stability and quality of the stored product. [ Main ingredients ] Ion water, Polyaminoacid resin, Auxiliaries agent, Tannis acid, Phosphoric acid, Gallic acid, all Heavy metals, Benzyl, Formaldehyde...etc. are not detected. [ Precautions ] Shut the pack tightly and keep it in a cool and dry place. Keep it away from kids and avoid to be eaten by mistake. If any emergency occurs, please flush with water immediately. 0809-000881 |

|

[ Note ] We also provide 50ml and 100ml capacities. If you have any questions about operation, please call us at 0809-000881. |